From Phillips to Torx: Exploring Different Types of Screwdriver Heads

Choosing the right screwdriver head is crucial for efficiently handling various fastening tasks. Different types of screwdriver heads are designed with specific features that cater to different needs, from precise work in electronics to heavy-duty applications in construction and automotive industries. Understanding the function and characteristics of these screwdriver heads helps users select the most suitable tool for the job. This ensures secure fastenings and prevents damage to both screws and surrounding materials. This article explores common types of screwdriver heads, their applications, and how to assess their functionality based on specific tasks. Mastering these distinctions allows users to optimize their tool selection and improve efficiency in everyday and specialized tasks.

Materials for Screwdrivers

The choice of material is crucial for the lifespan of screwdrivers. The material must balance the durability of the tip and the toughness of the screwdriver itself. If the hardness is too high, improper use can cause significant damage to screws. Conversely, if the hardness is too low, the wear resistance of the screwdriver decreases. It can be said that the use of different materials in screwdriver production leads to significant differences in quality.

1. Chromium-Molybdenum Steel (Cr-Mo)

This material is typically used to produce high-end screwdrivers and small hex wrenches. Chromium-molybdenum steel offers excellent impact resistance, as well as high hardness and toughness. It is an alloy of chromium, molybdenum, iron, and carbon, but it is relatively expensive.

2. Chromium-Vanadium Steel (Cr-V)

Cr-V steel combines good strength and toughness at a reasonable price, making it the preferred material for manufacturing wrenches, screwdrivers, and other tools. It is an alloy of chromium and vanadium, widely used in everyday screwdrivers and tools due to its affordability.

3. Carbon Steel (CS)

Carbon steel refers to a class of steel without specific alloying elements and with a carbon mass fraction less than 2.11%. It is known for its high hardness and strength but lacks toughness. While not ideal for screwdrivers, carbon steel is widely used in general-purpose tool materials.

4. S2 Tool Steel

S2 tool steel is an excellent impact-resistant steel used to make high-hardness hex wrenches, screwdrivers, and similar tools. After heat treatment, tools made from S2 steel exhibit high hardness, good wear resistance, and sufficient strength and toughness. However, it is not as commonly used in screwdriver applications as chromium-vanadium steel.

Different types of screwdriver heads

1. Flathead Screwdriver

The flathead screwdriver, also known as a slotted screwdriver or straight screwdriver, has a flat, chisel-shaped blade. It fits right into the slot of a screw head, but you gotta watch out—it can slip if you're really cranking on it.

Most folks keep this tool in their toolbox because it's handy in a pinch. Need to start your riding lawnmower but can't find the key? A flathead screwdriver can do the trick. Trunk latch acting up in your car? Bust it open with a flathead screwdriver. It's a go-to for lots of jobs and can even stand in for a Phillips screwdriver when you're in a jam.

2. Phillips Screwdriver

The Phillips screwdriver is favored by professionals and also known as a cross-head screwdriver. It is widely used from furniture to appliances. If you have a set of Phillips screwdrivers, only a few places require another type of screwdriver.

The tapered tip of this screwdriver is designed so that you can insert it deeper into the screw head without the risk of the blade protruding when exceeding a certain torque limit, i.e., slipping out of the head.

3. Torx Screwdriver

The Torx screwdriver is designed specifically for security purposes and is also known as a Torx security screwdriver. It is widely used in manufacturing.

The rounded star-shaped or floral design of the blade can provide high torque tolerance. Due to its star-shaped tip, it is also referred to as a star screwdriver. To tighten or loosen screws using a Torx screwdriver, you must purchase a specific size of screwdriver that matches the screw size.

4. Hex Screwdriver

Known as a hex screwdriver due to its hexagonal tip, it is designed to loosen and tighten hex nuts, bolts, and screws.

Tool steel is used to manufacture hex screwdrivers, and hex nuts, bolts, and screws passing through brass and aluminum are also made of brass. You can use hex screwdriver attachments to install most power drivers.

5. Robertson( Square ) Screwdriver

The country of origin of the Robertson screwdriver is Canada. Therefore, this screwdriver is common in Canada but not widely elsewhere in the world. It is highly durable, hence widely used in the automotive and furniture industries.

6. Triangular Screwdriver

The triangular screwdriver is characterized by its triangular-shaped tip, which matches the triangular recess on the screw head. It is primarily used in specific applications within the electronics and toy industries where manufacturers employ triangular screws as a security measure to prevent tampering or unauthorized access. The design of the triangular screwdriver allows it to engage securely with these screws, providing the necessary torque for tightening or loosening them as required. You can also use a hex screwdriver to tighten and loosen triangular screws, which is why it isn’t widely used.

7. Tri-wing Screwdriver

The tri-wing screwdriver is distinguished by its three-winged tip, resembling a Y-shape or three-point star. This type of screwdriver and screws are very popular in the electronics industry, used in devices such as power strips, mobile phones, game consoles, and other equipment. The tri-wing screwdriver's precise fit into these screws enables effective torque application for tightening or loosening them without damaging the screw head or surrounding components.

8. U-shaped Screwdriver

U-shaped screws have a pair of round holes near their ends, making them extremely robust to the point where they are nearly impossible to loosen without a U-shaped screwdriver. It features a unique flat blade with a pair of protruding tips at the end and is widely used in maintenance work at subway stations, bus terminals, elevators, or public restrooms.

9. Pozidriv Screwdriver

The Pozidriv screw drive system was developed by the American Screw Company in the 1960s to address limitations in the Phillips design. Enhanced functionality and reduced risk of cam-out have made Pozidriv the preferred choice across various industries, particularly in assembly lines and construction. The additional ribs in the Pozidriv design minimize the chances of camming out, ensuring a safer and more efficient fastening process. The cross-shaped design of Pozidriv is engineered to handle higher torque levels, making it suitable for critical applications requiring strong and reliable connections. It offers versatility in tool use, compatible to some extent with both Pozidriv and Phillips screws.

The importance of choose the right type of screwdriver head

Choosing the right type of screwdriver head is crucial for several reasons:

1.Prevent Damage

Using the correct screwdriver head prevents damage to both the screw and the tool itself. Using the wrong size or type can strip the screw head or damage the surrounding material, making it harder to remove or impossible to reuse. While properly using the right screwdriver head prolongs the life of both your tools and the materials you're working with.

2. High-efficiency

The right screwdriver head allows for efficient tightening or loosening of screws. This efficiency is not only about saving time but also about reducing the effort required and achieving a more secure connection.

3. Enhance user experience

Using an ill-fitting screwdriver head increases the likelihood of the tool slipping off the screw head. This can lead to injuries to your hand or damage to the workpiece. Ergonomically designed screwdriver handles, combined with the right head type, can make the tool more comfortable to use, reducing fatigue and the likelihood of mistakes.

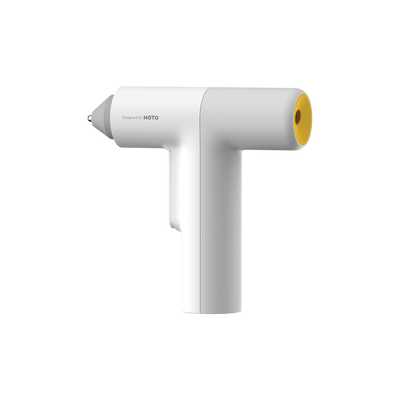

The benefits of using an electric screwdriver

Versatility

Many electric screwdrivers, like HOTO, come with interchangeable bits or attachments, making them suitable for various screw types and sizes. This versatility makes them ideal for a wide range of applications, from furniture assembly to automotive repairs. Convenient snap-on magnetic bit installation for quick and easy bit changes, enhancing your efficiency.

Easy to use

With the auto and manual modes, it can easily switch between automatic screwing with one press and manual screwing for precise control. The Intuitive forward-and-reverse button allow you to simply pick it up and screw in the screw. After the screw is tightened, it will automatically stop. This is because when the screw reaches the bottom and the resistance suddenly increases, causing an increase in current, sensors detect this increase and automatically cut off the power, allowing the product to stop automatically.

Portable

An electric screwdriver is portable primarily because of its compact size and lightweight design. Unlike larger power tools that require more substantial power sources or are bulky to transport, electric screwdrivers are typically smaller and easier to handle. They can be stored in a mini screwdriver kit, along with other accessories, like HOTO PRECISION SCREWDRIVER KIT PRO, which measures 182 x 71.3 x 26.1mm and weighs 314g, making it perfect for daily carry and use. It has 48 premium accessories, including 20 short and 6 long durable S2 steel bits, combining practicality and reliability for any project.

Summary

In conclusion, understanding how to judge the function of different types of screwdriver heads is essential for achieving efficient and effective results in various tasks. By recognizing the specific characteristics and applications of each type—whether it's the precision of a Phillips head, the enhanced grip of a Pozidriv, or the specialized uses of Torx and square heads—we empower ourselves to choose the right tool for the job. This not only ensures the integrity of the fastening process but also promotes safety, prevents damage, and ultimately enhances our overall productivity. Armed with this knowledge, professionals and DIY enthusiasts alike can confidently select the optimal screwdriver head for any project, from delicate electronics assembly to heavy-duty construction, thereby achieving superior outcomes with every turn.